Case Study – Thermoelectric Generators

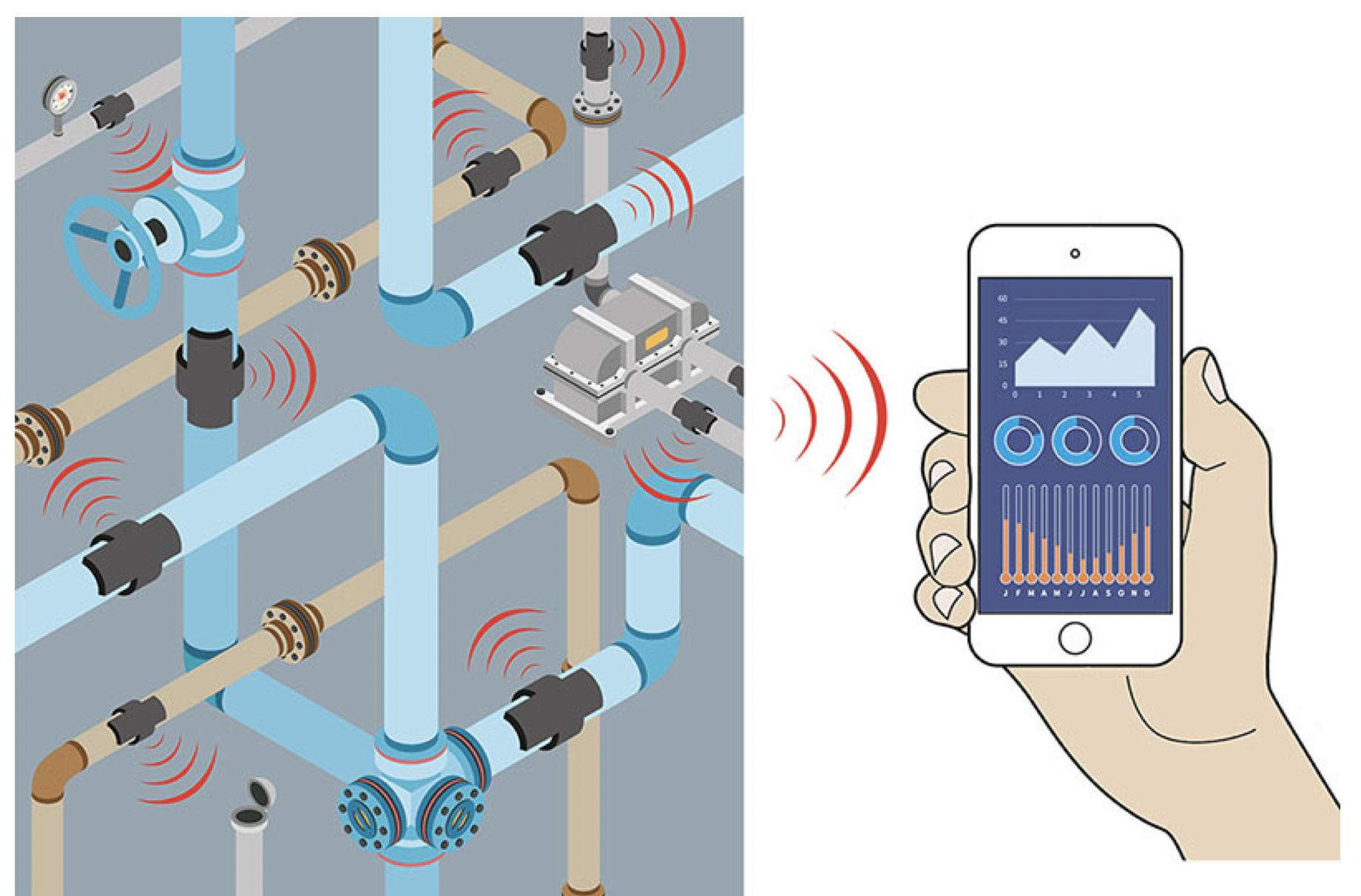

CDT has developed a solution to one of the challenges of providing power for ubiquitous electronics through the development of an organic thermoelectronic device platform to generate electric power from waste heat. Energy can be harvested from domestic and industrial hot surfaces, such as boilers, motors and steam pipes, and is sufficient to power IoT and wireless sensor networks.

Materials and processes were developed for thin and conformable thermoelectric generator (TEG) modules that can be manufactured using mainstream printing technologies. CDT’s TEGs are more cost-effective for low power applications than traditional thermoelectric generators. Their versatile form factor allows them to wrap around curved hot surfaces such as pipes.

CDT’s TEG modules can provide a ‘fit and forget’ power option for devices located in hard to reach areas such as wall or ceiling cavities and underground pipelines; or for dark areas where photovoltaics are not an option.